06 May What is a Cleanroom? A Simple Guide

As scientific progress advances and machinery and parts become smaller and smaller, the demand for cleanrooms will continue to grow. This is because, in many industries, cleanrooms are often necessary for creating safe and reliable products. Whenever small particles can cause issues, whether in manufacturing or science, cleanrooms are needed to ensure consistent outcomes.

What is a Cleanroom?

A cleanroom is a controlled environment that is designed to limit the size and number of airborne particles, including dust, microorganisms, and vapors. The purpose of a cleanroom is to limit contaminants within in a space, which makes it “clean,” so to speak. In some industries, such as aerospace and semiconductors, a single particle can cause major problems with products. As a result, cleanrooms have become necessary in improving product safety in many sectors of the economy.

Cleanroom Classifications

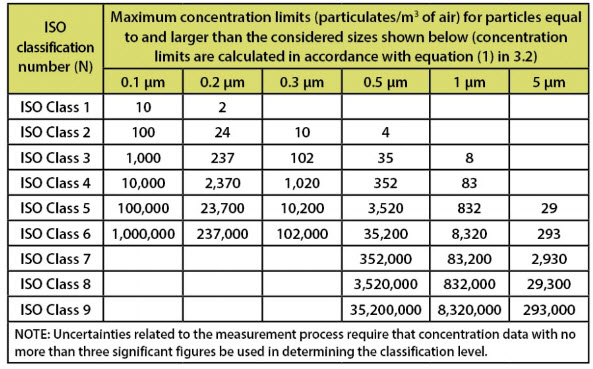

Cleanrooms are classified based on the number and size of particles allowed per unit volume of air. The International Organization for Standardization (ISO) defines classifications in its ISO 14644-1 standard. This standard categorizes cleanrooms into various classes ranging from ISO 1 to ISO 9, with ISO 1 being the cleanest and ISO 9 being the least clean.

- ISO 1: The strictest classification, allowing the least number of particles. It is typically used in advanced scientific research and semiconductor manufacturing.

- ISO 5: Often found in pharmaceutical manufacturing and biotechnology. This classification is considered mid-range, though they may require a lot of advanced features, such as unidirectional airflow and ULPA filters.

- ISO 7: Commonly used in medical device manufacturing, where some contamination control is necessary, but they are not as strict as higher classifications.

Each class specifies the maximum allowable concentrations of particles of specific sizes, measured in micrometers, also known as microns (µm). For instance, an ISO 7 cleanroom allows up to 352,000 particles per cubic meter of air for particles sized 0.5 µm or larger. Some cleanroom classifications will not measure certain particle sizes, as there are either too many to count or not relevant to the work typically done in those cleanrooms. ISO 7 environments, for example, do not measure particles less than 0.5 µm, as you can see below.

Additionally, cleanrooms often control other parameters such as temperature, humidity, and pressure, depending on the application. This is done to further prevent contamination and to meet other specific requirements for the cleanroom’s use. The maintenance and monitoring of these conditions are also important to ensure there are no lapses in the environmental controls.

What’s the Difference Between ISO and Federal Standard 209E?

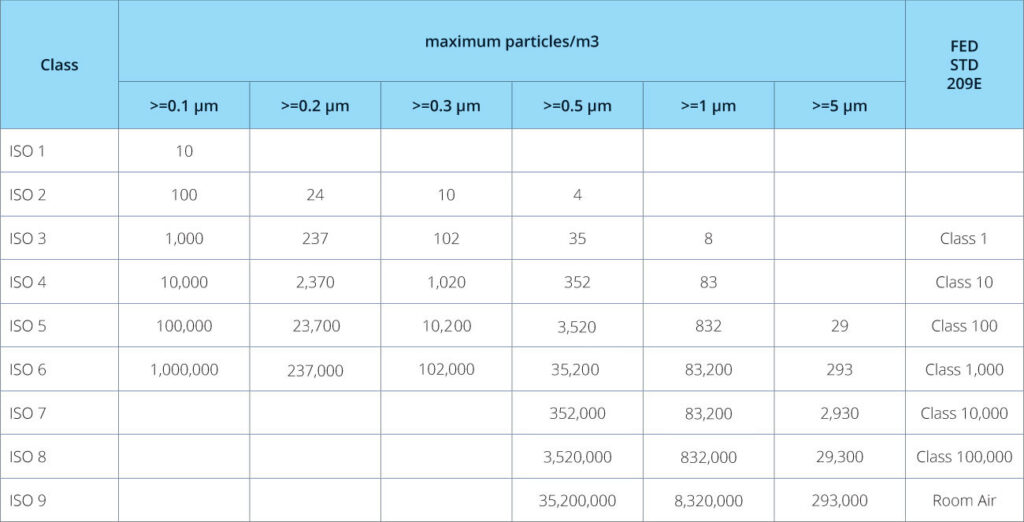

Historically, the Federal Standard 209E was the go-to classification system. It categorized cleanrooms based on the size and number of particles per cubic foot of air, rather than per cubic meter, as is this case with ISO classifications.

Today, the International Organization for Standardization (ISO) 14644-1 standard has replaced Federal Standard 209E. Though the Federal Standard 209E is no longer relevant, terms like “Class 10,000” or “Class 1,000” are still used for ease of reference.

Here is a table showing how the two standards are related.

The Parts of a Cleanroom

A cleanroom’s success depends on several factors, which combine together to make the room as clean as possible. Here are a few important aspects to consider when designing a cleanroom:

- Surface materials: Walls, ceilings, and floors should be made from smooth, non-shedding, and non-porous materials. This is done to make surfaces easy to clean and to prevent particles from accumulating in hidden or hard-to-reach places.

- Filtration systems: Advanced filters allow cleanrooms to remove problematic particles with ease. High-efficiency particulate air (HEPA) filters remove 99.97% of particles larger than 0.3 micrometers, while ultra-low particulate air (ULPA) filters remove particles bigger than 0.12 micrometers. Choosing the right filters depends on the size of the particles you need to avoid.

- Environmental controls: Special systems control temperature, humidity, and airflow. The specific environmental needs of each cleanroom may be different, depending on the industry.

- Personnel and material entry/exit systems: Air showers, pass-throughs, and personnel protocols can prevent contaminants from entering or leaving cleanrooms.

Types of Cleanrooms

Hardwall Cleanrooms

The term ‘hardwall cleanrooms’ is self-explanatory. They have hard walls. Manufacturers make them from materials like steel or aluminum, and they are more durable than their softwall counterparts. As a result, they are (in general) better at environmental control than softwall cleanrooms.

Modular cleanrooms are one type of hardwall cleanroom, and they are prefabricated in a factory before being delivered. They are more flexible and can be installed quickly, while permanent structures may take significantly longer to construct. Typically, modular cleanrooms are better for organizations that may need to change, adapt, or expand their environments at a later date.

Softwall Cleanrooms

Softwall cleanrooms, on the other hand, use soft materials for walls, such as vinyl curtains.

These cleanrooms are generally much cheaper, though they are not as effective as hardwall cleanrooms. As a result, they are typically used in less strict ISO classes, such as ISO 7 or 8.

Like modular cleanrooms, you can easily move or expand them.

Applications of Cleanrooms

A huge variety of industries use cleanrooms. Here a few sectors that rely heavily on them:

- Pharmaceuticals and biotech: Drug manufacturing can be dangerous if certain particles or germs contaminate the products.

- Semiconductor and electronics manufacturing: In these industries, even a single particle can ruin a component.

- Aerospace and defense: In these industries, too, even small particles can cause catastrophic malfunctions with parts, which makes avoiding contamination a matter of life and death.

- Healthcare and medical devices: Sterile conditions are necessary in these industries because contamination can lead to infections in patients or failure of equipment.

- Food and beverage: Cleanrooms prevent bacteria, mold, and other germs from getting into food products so that they are safe to eat or drink.

Cleanroom Protocols and Practices

Successful cleanroom operation relies on many routine protocols, including:

- Proper gowning procedures: Wearing gloves, face masks, and coveralls to prevent human-borne contamination (via skin cells, hair, or other contaminants) into the cleanroom.

- Cleaning and maintenance protocols: Regular cleaning with non-shedding wipes and approved chemicals.

- Monitoring and testing: Routine particle counting and microbial testing.

- Risk management: Risk assessments help identify possible contamination issues.

The Bottom Line

Cleanrooms are essential for organizations and businesses that need to avoid certain particles, whether viable or non-viable. Given the recent advances in cleanroom technology, these spaces are becoming better and better at preventing contamination, and their importance will only continue to grow as components shrink. If you’re considering a cleanroom for your organization, get a free quote from Allied Cleanrooms today.