25 Mar What is a Controlled Environment? Understanding the Basics

Controlled environments are used in many industries, stretching from manufacturing and research to seemingly unrelated areas like film production and agriculture. In this article, we’ll go over the definition of a controlled environment, some common factors that are ‘controlled’, and the differences between controlled environments and cleanrooms.

What is the Definition of ‘Controlled Environment’?

A controlled environment, also known as a critical environment, is an enclosed space where specific environmental conditions, including air temperature, humidity, particle levels, light, and other factors, are managed. These environments are essential in many industries, such as manufacturing, research, agriculture, and even film production.

The purpose of each controlled environment differs, of course, depending on its use. The term is not very specific, and it encompasses various types of spaces.

Let’s examine a few conditions that some controlled environments try to manage (especially in a manufacturing or research context), as well as the industries that depend on such conditions.

Temperature Control

Temperature is an important factor in many manufacturing processes and research activities. The temperature can affect everything from the strength and condition of materials to how efficient chemical reactions are.

In food manufacturing facilities, for example, it’s especially important to keep the temperature just right. If a food production facility becomes too hot, moisture can build up, leading to the growth of microorganisms. This could potentially make the food unsafe for consumers. Even small changes in temperature can have big effects on products and processes.

Humidity Control

Humidity is another important factor in many controlled environments.

If air is too humid, it can cause rust, mold, or damage to materials. On the other hand, if the air is too dry, it can create static electricity or dry out items.

In semiconductor manufacturing, for instance, it’s crucial to maintain proper humidity levels. Static electricity can build up in low humidity environments, which could cause serious damage to semiconductor units.

Getting humidity right is crucial for keeping products safe and in good shape, especially in making things like computer parts.

Particle Control

Controlling tiny particles, such as dust, microbes, and vapors, is another important factor to manage in making sure that products are clean and working right. Some products are so sensitive that even a few small particles of dust can cause issues.

Take the aerospace industry, for example. When manufacturing components for spacecraft, any contamination by dust or other particles can jeopardize critical systems.

Tiny particles of dust may cause failure in navigation systems or engines, risking missions and lives. For this reason, a lot of aerospace manufacturing takes place in cleanrooms, which are a specific type of controlled environment. These environments ensure that air contains a limited number of particles.

Cleanrooms vs. Controlled Environments: Are They the Same?

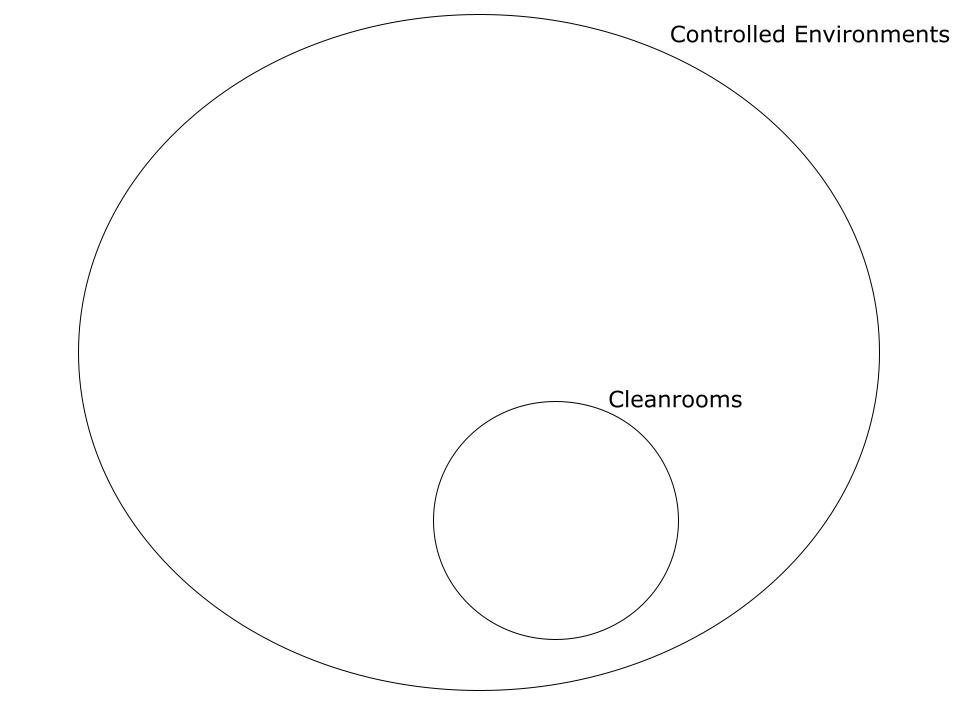

Cleanrooms, in short, are a type or kind of controlled environment. While all cleanrooms are controlled environments, not all controlled environments are cleanrooms.

Controlled environments cover a wider range of settings. There are many types of controlled environments, such as dry rooms, laboratories, and greenhouses, that are not classified as cleanrooms.

Cleanrooms, instead, place strict and specific limits on both the size and number of particles in the air. They follow rigorous standards for air cleanliness and may include advanced filtration systems (HEPA/ULPA), special materials for walls and surfaces, and even unidirectional air flow systems.

In general, controlled environments (unless they are cleanrooms) do not have to meet air particle standards, such as ISO 14644-1. Though cleanrooms may also control air temperature and humidity, they always have to control air particle counts.

Which Environment Fits Your Project?

Figuring out which type of environment your project needs is not always clear cut. Our engineers at Allied Cleanrooms can help you clarify things. (Get a free quote, on us.) We provide a wide range of cleanroom and controlled environment solutions tailored to ensure your project’s success.