15 Apr Aerospace Cleanrooms: Standards, Design Features, and More

Manufacturing reliable components in the aerospace industry is a matter of life and death. As a result, contamination control is a necessity. At Allied Cleanrooms, we recognize the importance of our work. Our aerospace cleanroom environments are designed with the safety of each component in mind, from tiny sensors to large spacecraft modules. In this article, we’ll explore the key aspects of aerospace cleanrooms, including their classifications and the advanced features that define them.

What is an Aerospace Cleanroom?

Aerospace cleanrooms are necessary for the manufacturing, assembly, and testing of aerospace products. These controlled environments help prevent small particles from entering sensitive components, avoiding both minor defects and catastrophic malfunctions.

Uses of Aerospace Cleanrooms

Aerospace cleanrooms have a variety of uses within the industry. Such applications include aircraft engine assembly, spacecraft component development and manufacturing, and the assembly of sensitive electronic systems.

Standards and Classifications

ISO 14644-1 Standards

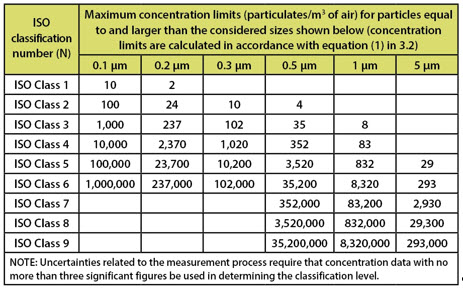

Aerospace cleanrooms follow the cleanroom classifications outlined in ISO 14644-1, which sets limits on the number and size of airborne particles.

For aerospace applications, cleanrooms often need to meet at least ISO Class 7 (Class 10,000) standards. Equipment that is more sensitive to smaller particles, such as optical devices, lasers, sensors, and other electrical equipment, may need much cleaner enclosures.

ISO 14644-1 sets cleanliness standards for aerospace cleanrooms by specifying acceptable levels of contamination for each ISO class.

In order to meet these standards, our engineers will consider the following:

Particle Counts: To maintain standards, it’s important to measure particles of specific sizes in each cubic meter of air. The stricter the ISO class, the tighter the limits on particle size and number.

Air Changes Per Hour (ACPH): This is an air change rate that describes how quickly air is completely replaced in one hour. Generally, the stricter the ISO class, the more ACPH will be necessary to meet standards. An ISO 7 cleanroom, for example, requires about 60 ACPH. This means that the air is replaced around one time every minute. On the other hand, an ISO 4 cleanroom may require up to 700 ACPH to meet standards, which would mean that the air is replaced roughly 11 times per minute.

Ceiling Coverage: This refers to the required percentage of a cleanroom’s ceiling that should be covered by HEPA filters and fan filter units (FFUs), which are key components of cleanroom HVAC systems. Generally speaking, the more ceiling coverage, the cleaner the room. A higher ceiling coverage percentage can remove particles quicker.

ISO 14644-2 Standards

The ISO 14644-2 standard focuses on testing and monitoring aerospace cleanroom processes, and it is used to guarantee continued compliance with the standards set out in ISO 14644-1. Given the high cost of failure in the aerospace industry, this part of the ISO framework is critical to making sure that cleanrooms work as they should.

ASTM and NASA

Our engineers are able to help aerospace cleanrooms comply with the American Society for Testing and Materials (ASTM) standards, as well as NASA regulations.

ASTM has developed International Standards that assess a cleanroom’s ability to control contamination by setting limits on particle levels and by addressing specific technical requirements. These requirements focus on controlling mechanical, thermal, chemical, and electrical properties.

Aerospace cleanrooms must meet ASTM standards relevant to their material uses, including regulations on combustible fuel management, static control systems, and manufacturing processes for sensitive parts, such as spacecraft hardware, fine electronics, and optical devices.

Design and Features of Aerospace Cleanrooms by Allied Cleanrooms

Modular Design

Allied Cleanrooms specializes in modular cleanrooms that are fully customizable to meet the specific requirements of aerospace manufacturing and testing (including ISO, NASA, and ASTM). We have worked with many high-profile clients in the industry, including SpaceX, JPL, Boeing, the U.S. Airforce, and even NASA themselves.

Allied Cleanrooms offers many types of cleanrooms for the aerospace sector that are completely adaptable and reconfigurable. These modular cleanrooms feature insulated panels tailored to your specific needs to maintain a clean atmosphere, protect against contaminants, and provide complete environmental control.

Compared to constructing a cleanroom on location, Allied Cleanrooms’ modular solutions are simpler and more cost-effective to install, while also delivering enhanced control, performance, and energy efficiency. They can be reassembled to meet your changing business needs, making them both eco-friendly and economical.

Advanced Features

Key features of these cleanrooms include high-efficiency particulate air (HEPA) filtration systems that trap microorganisms and fine particles. They can also be configured to control specific environmental conditions, such as temperature, light, humidity levels, and more.

In addition, Allied Cleanrooms designs cleanrooms with non-outgassing and silicone-free components. We also include electro-static discharge materials to protect both employees and products.

Smart Monitoring Systems

The use of smart monitoring systems allows for real-time control and measurement of environmental variables. This guarantees ongoing adherence to ISO 14644-1 standards and other relevant aerospace regulations. This technology allows for quick detection and correction of any deviations.

Customization

Allied Cleanrooms provides the cleanroom design spaces that are tailored and ready-made for specific applications. Whether it’s a facility designed for the assembly of spacecraft system hardware or for the manufacturing of contamination-sensitive components, each cleanroom environment is made to meet exact specifications and standards. If you’re looking to build and customize an aerospace cleanroom project, reach out today to get a free quote.

Aerospace Cleanrooms: The Bottom Line

Aerospace cleanrooms are vital for maintaining the safety of aerospace manufacturing processes. With strict standards and advanced features for environmental control, cleanrooms designed by Allied Cleanrooms allow organizations in the aerospace industry to meet their quality assurance demands. As cleanroom technology improves, these facilities will continue to improve component reliability and safety.