18 Apr Aerospace Cleanroom Requirements: What You Need to Know!

Aerospace cleanrooms are controlled environments that are designed to limit the number and size of tiny particles. These microscopic contaminants can disrupt the manufacturing, assembly, and testing of important aerospace components. As a result, aerospace cleanrooms ensure the safety and reliability of aerospace products, where even dust can lead to catastrophic failures in equipment and technology. In this article, we’ll discuss the essential requirements for managing an aerospace cleanroom.

Environmental Control Requirements in Aerospace Cleanrooms

The aerospace industry requires cleanrooms that can maintain specific environmental conditions. Depending on their use, aerospace cleanrooms, in addition controlling airborne particle levels, may also manage temperature, humidity, pressure, and more.

Additionally, to control the airborne particle counts, these cleanrooms will need to make use of advanced filtration technology. Such aerospace manufacturing environments use high-efficiency particulate air (HEPA) and ultra-low particulate air (ULPA) filters to control the entry of very small particles.

HEPA filters can block 99.97% of particles that are 0.3 micrometers, and this may be sufficient for some aerospace applications. However, other applications sometimes need to prevent even smaller particles from causing issues. Since ULPA filters can stop 99.99% of particles that are 0.12 micrometers, these filters are used to protect more sensitive products.

Cleanroom engineers decide which filters to use based on the size of particles that cause problems in aerospace products.

Global and Industry-Specific Standards for Aerospace Cleanrooms

While ISO standards provide a framework for aerospace cleanroom projects, they may also need to comply with industry regulations, such as the ASTM standards or NASA requirements, which can include even stricter controls depending on the sensitivity of the components being manufactured.

ISO Requirements

As far as ISO requirements go, cleanrooms in the aerospace sector have to comply with both ISO 14644-1 and ISO 14644-2.

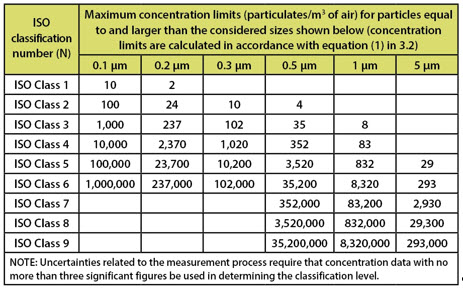

To comply with ISO 14644-1 standards, an aerospace cleanroom has to reach specific airborne particle counts, which are limited both by their size and number. There are nine ISO classes for cleanrooms, but the aerospace industry generally uses ISO Class 7 (Class 10,000) cleanrooms and below.

In order to adhere to ISO 14644-2, aerospace cleanrooms use monitoring systems that continuously measure particle counts and other environmental parameters. This constant watch helps maintain the required standards, and it shortens the response time in correcting any issues with the environment.

Get Your Project Started — Request a Free Quote Today!

If you’re ready to ensure that your aerospace operations meet the highest cleanroom standards, connect with our experts now and get a free quote tailored to your specific needs.

ASTM Requirements

The American Society for Testing and Materials (ASTM) has established standards that measure a cleanroom’s effectiveness in managing contamination through particle level thresholds and specific technical criteria. These criteria are designed to manage various properties, including mechanical, chemical, electrical, and thermal attributes.

It is essential for aerospace cleanrooms to adhere to relevant ASTM standards, which depend on their specific material applications. Some guidelines regulate combustible fuels, static control systems, and the production processes of sensitive components, such as spacecraft equipment, electronics, and optical instruments.

Personnel and Safety Protocols

Staff working in aerospace cleanrooms undergo rigorous training on cleanroom protocol, including how to properly wear cleanroom garments and handle tools and materials to reduce contamination.

Entering a cleanroom typically involves multiple stages of gowning, from basic coveralls to face masks and gloves, all designed to trap contaminants that could be introduced by the human body.

Aerospace Cleanroom Requirements: The Bottom Line

Aerospace cleanrooms play an increasingly important role in the industry, providing the controlled environments necessary for the high-precision manufacturing required in this field. As technology advances and components become smaller, these facilities will evolve, incorporating new materials, technologies, and practices to meet increasingly stricter standards.