20 May What are the Requirements for an ISO 4 Cleanroom?

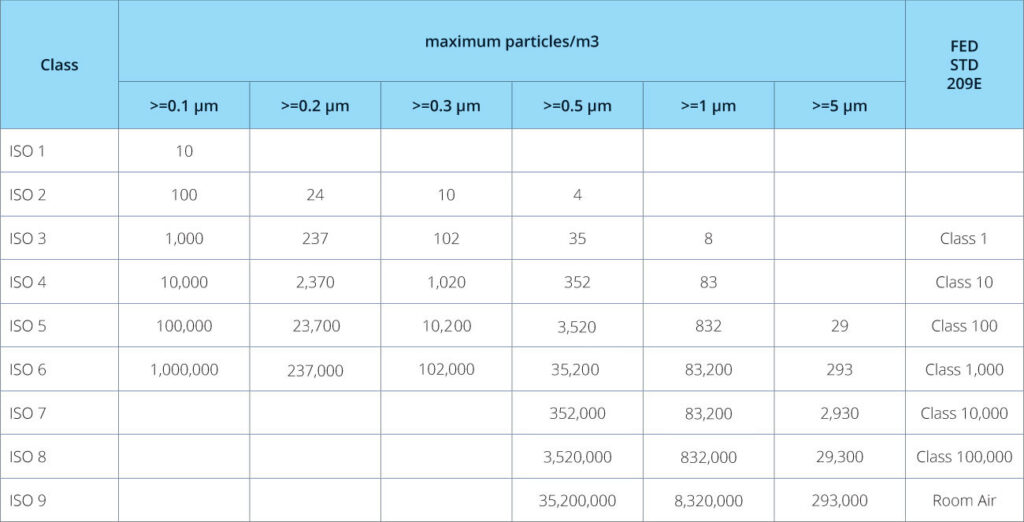

Cleanrooms, and especially ISO 4 cleanrooms, have a lot of complex requirements that can seem difficult at first for a non-technical audience. Fundamentally, though, cleanroom requirements are all about managing airborne particles. The main difference between each ISO classification (from ISO Class 1 to ISO Class 9) lies in the number and size of particles allowed. In this article, we’ll focus on ISO 4 cleanrooms, detailing their specific design, operational, and certification requirements.

What is an ISO 4 Cleanroom?

An ISO 4 cleanroom, according to ISO 14644-1 standards, is a highly controlled environment that limits the number and size of airborne particles, allowing no more than 10,000 particles (0.1 micrometers or larger) per cubic meter. They require 300 to 540 air changes per hour and often use unidirectional (laminar) airflow or a mix of laminar and turbulent airflow. This makes them stricter and more expensive than ISO 5–9 classifications.

In each cubic meter of air, they allow:

- 10,000 particles for sizes 0.1 micrometers or larger

- 3,520 particles for sizes 0.2 micrometers or larger

- 1,000 particles for sizes 0.3 micrometers or larger

- 352 particles for sizes 0.5 micrometers or larger

- 83 particles for sizes 1 micrometer or larger

- 10 particles for sizes 5 micrometers or larger

Keep in mind that these limits are cumulative, which means that a single particle counts towards the limits of all smaller size categories. ISO Class 4 cleanrooms permit fewer airborne particles than ISO 5–9 classifications, which makes them among the cleanest environments possible. They are often used in industries such as nanotechnology, semiconductor manufacturing, biotechnology, and pharmaceuticals.

If you’re planning to build an ISO 4 cleanroom, get a free quote from Allied Cleanrooms to make sure you meet all necessary standards.

What are the Requirements for an ISO 4 Cleanroom?

Fulfilling the ISO 4 classification requirements involves strict criteria in many areas. Here are some of the most important factors:

Ultra-Low Particle Counts

As we outlined above, ISO 4 cleanrooms permit a maximum number of particles per cubic meter of air at various sizes. Particle counters are used consistently to make sure that the space stays within proper limits. See the ISO classification chart below for the specific size and number of particles that they allow.

Advanced Filtration & Airflow

To keep the air pristine, ISO 4 cleanrooms use HEPA (High-Efficiency Particulate Air) filters, which remove at least 99.97% of airborne particles of 0.3 micrometers or larger, and ULPA (Ultra-Low Particulate Air) filters, which remove at least 99.9995% of airborne particles of 0.12 micrometers or larger.

Additionally, ISO 4 cleanrooms require at least some unidirectional airflow (also called laminar airflow). Unidirectional airflow moves in a parallel pattern that can be either vertical or horizontal. Often, these cleanrooms use a mix of both laminar and ‘turbulent’ airflow.

Furthermore, air changes per hour in these cleanrooms range from 300 to 540, with ceiling coverage, referring to the percentage of the ceiling covered by HEPA or ULPA fan filter units, usually between 50–90%

Surface and Material Requirements

Generally speaking, the surfaces in an ISO 4 cleanroom must be smooth, non-porous, and easy to clean. This avoids particle accumulation in hard-to-reach or hidden places. Similarly, coving is used to remove 90° angles, which can make surfaces easier to clean.

It is also important that the materials do not shed, as this would lead to further contamination. As a result, materials like polymers and stainless steel are used.

Regarding flooring, resinous material is common for its durability and ease of cleaning. In some applications, perforated tiling may be better.

Personnel Protocol

Gowning procedures are mandatory for all personnel entering an ISO 4 cleanroom. Personnel will need to wear bunny suits, head covers, beard covers, foot coverings, face shields, and gloves appropriate for the task. Regular training is necessary to make sure that all staff are following the rules correctly.

Monitoring

It’s always important to have regular monitoring and inspection. Real-time monitoring systems can provide quick and actionable data if the environmental conditions begin to deviate from standards. Regular maintenance ensures that all equipment and systems function correctly and efficiently.

Testing & Certification

These cleanrooms undergo rigorous testing and certification as specified in ISO 14644-2. The certification process involves several tests:

- Particle Count Testing: Conducted every six months, this test measures the number of airborne particles to ensure compliance with ISO 14644-1 Annex A.

- Air Pressure Cascade Testing: Also required every six months, this test checks the air pressure differentials between cleanroom areas to maintain contamination control, following ISO 14644-1 Annex B5 procedures.

- Airflow Testing: This test, also conducted every six months, assesses the uniformity and direction of airflow within the cleanroom, as detailed in ISO 14644-1 Annex B4.

The Bottom Line

ISO 4 cleanrooms are ultra-clean environments, and they are considered one of the cleanest classes. Through their rigorous requirements, they ensure the quality of products and protect sensitive scientific processes. As products continue to shrink in size and become more liable to contamination, the need for these spaces will only grow.