04 Apr Why are Hospital Cleanrooms Important in Modern Healthcare?

Few people know that hospitals were the first places to use cleanrooms. In the 19th century, a British surgeon named Lord Lister believed that bacteria were responsible for the many deaths that occurred after surgeries. To test his theory, he sprayed a disinfectant solution (carbolic acid) in his operating room in Glasgow, Scotland. He sprayed it into the air, on his hands, the wounds of patients, and his surgical tools.

To his astonishment, he found that the solution had reduced after-surgery deaths by about two-thirds, or 66%. Today, the legacy of this discovery continues, and the pursuit of safe and sterile spaces within hospital walls has saved the lives of countless patients. Hospital cleanrooms, inspired by Lister’s antiseptic method, continue to safeguard patients against infection.

How are Cleanrooms Used in Hospitals?

A cleanroom is a controlled environment where pollutants, such as dust, microorganisms, and vapors, are kept within strict limits. In hospitals, cleanrooms are essential for operating rooms, pharmacies, isolation rooms, or any spaces where the minimization of dangerous microorganisms is necessary. Cleanroom technology in hospitals has been particularly important over the last few years in reducing the transmission COVID-19.

Standards and Regulations for Hospital Cleanrooms

The healthcare industry, and hospitals included, have to follow a large list of regulations to make sure patients are kept safe and that spaces remain sterile.

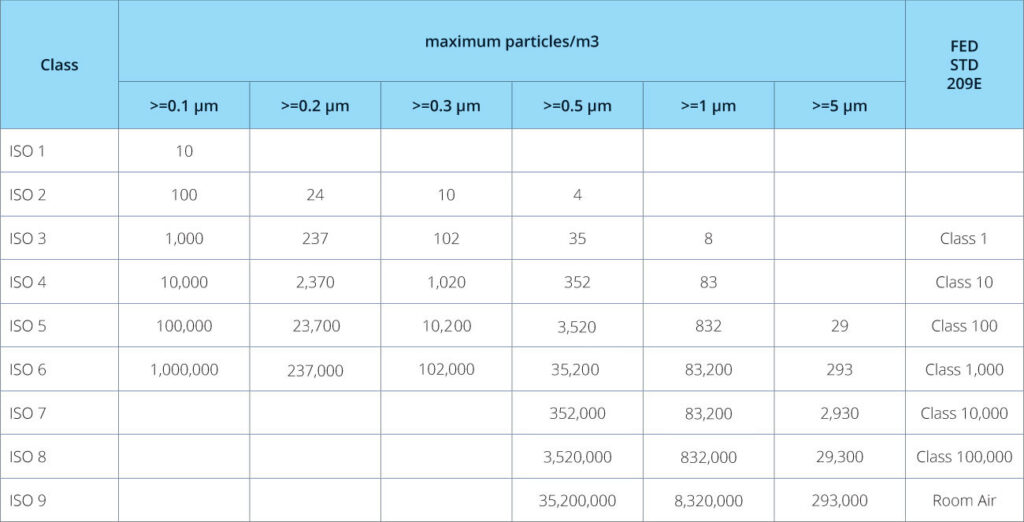

For cleanrooms, the International Organization for Standardization (ISO) provides the classification system ISO 14644-1, which outlines various levels of air cleanliness.

Hospitals typically require cleanrooms ranging from ISO Class 5 to ISO Class 8, depending on the application. An ISO Class 5 cleanroom, for instance, is needed for critical areas where the highest level of cleanliness is essential.

In addition to these ISO standards, hospital compounding and filling rooms may also have to follow USP 797 and USP 800 guidelines to ensure medications are safe and contamination-free. GMP (Good Manufacturing Practice) or cGMP (Current Good Manufacturing Practice) principles may also apply to ensure consistent and high-quality preparation of medications.

By adhering to these combined standards—ISO, USP, GMP/cGMP/FDA—hospitals can ensure a safe and effective environment for patient care.

Design and Construction of Hospital Cleanrooms

Cleanroom design depends very much on its use. For example, an operating room will not have the same design as an isolation room, though similar factors may be controlled in each. Let’s go over some of the factors that hospital cleanrooms control and how they might be used in different areas.

Pressurization

Pressurization is key to making sure dangerous bacteria and microorganisms stay in the right place. Hospital cleanrooms use pressure to make sure airflow moves correctly, especially to counter any air leaks from surrounding spaces.

Positive Pressure Rooms

In hospitals, some areas need tighter security against infectious agents than others.

Positive pressure rooms offer one such solution. They use pressure differentials to make sure that air from surrounding rooms cannot enter. A positive pressure room will have higher pressure than the surrounding rooms, and will push air outside the room if there is a breach.

In an operating room, for example, positive pressure may be used to make sure air from adjoining rooms cannot carry in dangerous pathogens. The air will instead flow out of the operating room and into the adjoining room, protecting patients from infections.

Negative Pressure Rooms

Negative pressure rooms, on the other hand, keep and contain pathogens. They maintain a lower air pressure inside than in the surrounding areas. If a breach occurs, the pressure differential will draw air into the negative pressure room, preventing contaminated air from escaping.

This has been especially useful in the last few years, with the so-called isolation rooms designed to prevent the spread of COVID-19 and other infectious diseases.

Humidity

Humidity is another important factor that some hospital cleanrooms need to control. In an operating room environment, for example, humidity levels may affect blood coagulation, anesthetic gases, and even some of the electrical equipment (low humidity levels can create a lot of static electricity).

Keeping hospital cleanrooms at the right humidity levels is essential to minimize disruptions and protect patients.

Airflow

Another key factor that is managed in hospital cleanrooms is airflow; its direction, velocity, and volume are often carefully controlled.

In operating rooms, for example, laminar airflow (also called unidirectional airflow) is used over the operating table to prevent dangerous infections that may occur during surgery. The speed or velocity of the air is also important, as the faster the speed of the air, the cleaner the area around the patient is.

HEPA and ULPA filtration

Hospital cleanrooms also use high-efficiency particulate air (HEPA) and ultra-low particulate air (ULPA) filtration to reach proper particle levels. HEPA filters can stop 99.97% of particles 0.3 micrometers or larger, and ULPA filters can stop 99.99% of particles 0.12 micrometers or larger.

These filters are much better at removing airborne particles than the air filtration systems used in a typical office environment, and they are typically installed right at the point where fresh air enters the room.

By using these filters, hospital cleanrooms can lower particle counts to ensure that certain environments are sterile.

Maintenance and Monitoring of Cleanrooms in Hospitals

Rigorous cleaning protocols, continuous monitoring of air quality, and extensive personnel training are also important in maintaining a cleanroom. Environmental monitoring tools measure particles, temperature, humidity, and other parameters to ensure ongoing compliance with standards.

Protect Patient Health with Allied Cleanrooms

If you’re looking to enhance or establish cleanroom facilities in your hospital or healthcare environment, it’s important that you speak with experts. Medical device manufacturers and healthcare providers can benefit from the expertise of Allied Cleanrooms. Our engineers at Allied Cleanrooms have over 30 years of hands-on experience in creating clean spaces. We offer comprehensive support from the initial design to construction. Get in touch for a personalized quote today!