13 May ISO 5 vs ISO 7 Cleanrooms: What’s the Difference?

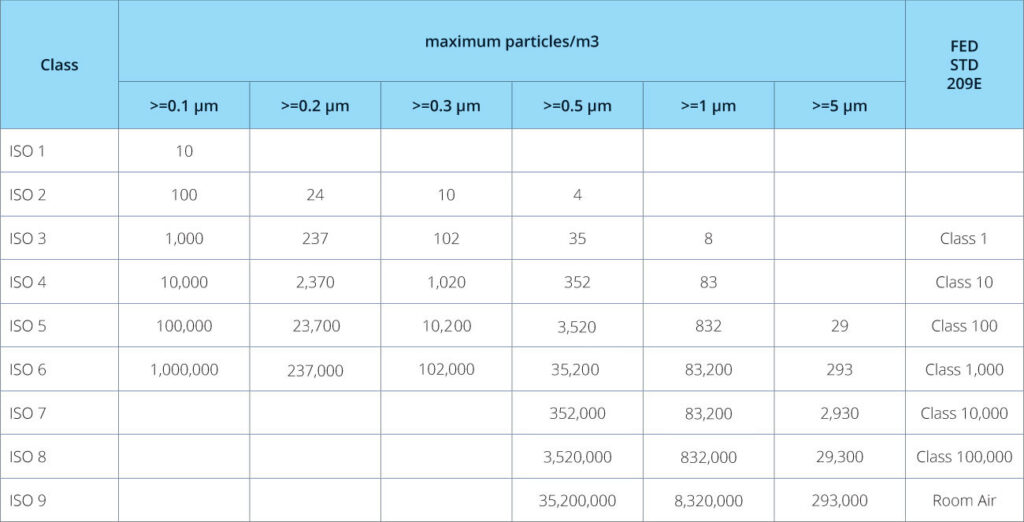

In the context of cleanrooms, ISO standards are important for categorizing the cleanliness of different environments. In a nutshell, ISO standards place limits on the number and size of particles allowed in the air. Cleanrooms are standardized to make quality and safety consistent, to make following rules easier, and to cut costs. However, the differences between ISO classes is often confusing or unclear for a non-technical audience. In this article, we’ll compare ISO 5 vs ISO 7 cleanrooms, as well as cover some common applications for each.

Comparing ISO 5 vs ISO 7 Cleanrooms

The main difference between ISO 5 vs ISO 7 cleanrooms is that ISO 5 cleanrooms permit fewer particles than ISO 7 ones. As a result, ISO Class 5 environments require higher air change rates and unidirectional airflow. This makes ISO 5 cleanrooms, all else being equal, more expensive than their ISO 7 counterparts. Let’s take a look at what specifically sets these cleanroom classes apart.

| ISO 5 Cleanrooms | ISO 7 Cleanrooms | |

|---|---|---|

| Particle Counts (per cubic meter at 0.5 micrometers) | Up to 3,520 particles | Up to 352,000 particles |

| Air Changes per Hour | 240 to 600 | 30 to 60 |

| Relative Cost | Higher cost because of frequent air changes, stricter particle limits, and unidirectional air flow requirements | Lower cost because of fewer air changes and higher particle tolerance |

| Common Applications |

|

|

Particle Counts

- ISO 5 Cleanrooms: These spaces allow up to 3,520 particles 0.5 micrometers or larger per cubic meter.

- ISO 7 Cleanrooms: These allow up to 352,000 particles per cubic meter for particles 0.5 micrometers or larger, which is 100 times more than the particle count permitted in ISO 5 cleanrooms.

Additionally, as you can see below, particles smaller than 0.5 micrometers are not measured in ISO 7 cleanrooms. This is because there are far too many of them, and the smaller particles have a minimal impact on the work done in these rooms.

Air Change Requirements

A high air change rate keeps cleanrooms clean. Air changes per hour measures how frequently the air in a room is replaced with fresh air within an hour. The higher the number, the cleaner the room will be.

- ISO 5 Cleanrooms require anywhere from 240 to 600 air changes per hour to maintain particle levels.

- ISO 7 Cleanrooms typically need around 30 to 60 air changes per hour to keep up with standards, which is much less strict than ISO 5.

Relative Costs

- Costs for ISO 5: Because of the need for frequent air changes to maintain lower particle levels, construction and operational costs will be higher. Additionally, these rooms will need to make use of unidirectional air flow, which will likely push costs up even further.

- Costs for ISO 7: With fewer air changes needed and a higher tolerance to particles, these cleanrooms are far less expensive to make and operate.

Applications of ISO 5 Cleanrooms

ISO 5 cleanrooms are important in industries where especially small particles can cause serious issues. In some of these sectors, even a single particle can cause a malfunction:

- Semiconductor manufacturing (photolithography): Protects the patterns created on wafers, which are sensitive to contamination.

- Pharmaceuticals (filling rooms): Used for putting medications in their final packaging; prevents contamination of drugs.

- Aerospace: Prevents particles from disrupting products during manufacturing; aerospace components, when contaminated, can lead to catastrophic failures that risk lives.

- Medical devices: Preserves device safety and functionality, protecting patients.

Applications of ISO 7 Cleanrooms

ISO 7 cleanrooms are less strict than their ISO 5 counterparts, but they are still necessary for many manufacturing and research processes. Here are a few sectors where they are useful:

- Biotechnology research and development: Protects the accuracy of experimental results.

- IV compounding: Keeps the environment safe for intravenous medicines.

- Food processing: Prevents dangerous organisms from spoiling food products.

- Optical manufacturing: Stops dust and other particles from damaging the quality of lenses and other parts.

The Bottom Line

The choice between ISO 5 vs ISO 7 cleanrooms depends in large part on the specific particle sizes that cause issues with your manufacturing or research processes. Additionally, an understanding of regulations and requirements is important in any cleanroom project. If you’re unsure about what cleanroom classification suits your needs, seeking advice from experts is the right way to go. Don’t compromise on your cleanroom requirements — contact Allied Modular for expert advice and a free quote today.