23 May What are ISO Cleanroom Standards? Why are They Important?

Cleanrooms are necessary in any industry where controlling particles, whether viable or non-viable, is a factor in product safety. Not to mention scientific research, where a clean environment can make the difference between reliable and unreliable results. The needs of each cleanroom can differ drastically, which is why the International Organization for Standardization (ISO) established a set of standards, known as ISO 14644.

The purpose of this standard is to provide a universally consistent framework for designing, classifying, testing, and monitoring cleanrooms. It allows everyone to be on the same page, so to speak. When cleanrooms are built and maintained with some degree of uniformity, it makes it easier for companies to meet safety and quality requirements and for regulators to check that cleanrooms are up to standard.

While the ISO 14644 series includes several parts—like ISO 14644-2 for monitoring and ISO 14644-3 for test methods—this article will focus on ISO 14644-1, which deals with cleanroom standards.

ISO 14644-1: Cleanroom Classifications

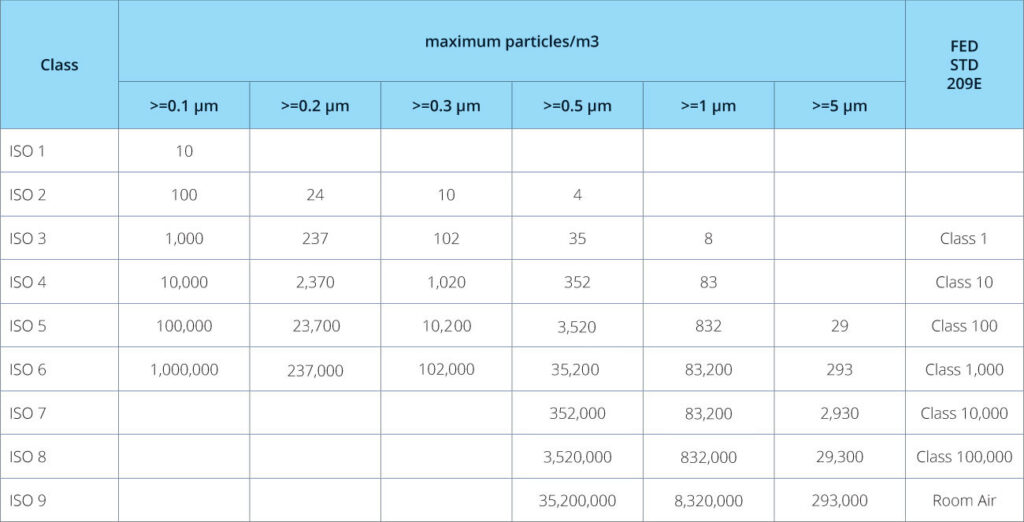

ISO 14644-1 classifies the cleanliness of air in cleanrooms by specifying limits on the size and number of airborne particles allowed in each class or category. There are nine ISO classes, from ISO Class 1 (the cleanest) to ISO Class 9 (the least clean).

Classification Levels

- ISO Class 1: Very few applications of this class exist. They allow the fewest particles, and they are suitable for the strictest environments, such as are required in semiconductor manufacturing.

- ISO Class 2-3: Common in high-precision industries, such as nanotechnology.

- ISO Class 4-6: Considered “mid-range.” Used in biotechnology, pharmaceuticals, and medical device manufacturing.

- ISO Class 7-8: These spaces are much more tolerant of particles. Used in industries such as food processing and basic electronic assembly.

- ISO Class 9: The least strict cleanroom class. Used for general manufacturing processes that still require some level of contamination control.

How Cleanrooms Meet ISO Standards

To classify a cleanroom according to ISO 14644-1, technicians use particle counters. These instruments measure the concentration of particles of various sizes per cubic meter. Cleanrooms are regularly monitored to ensure these spaces stay within limits.

Aside from monitoring and testing, there are many other factors that contribute to cleanliness. Here are a few of the most important:

- HEPA/ULPA Filters: Using high-efficiency particulate air (HEPA) or ultra-low particulate air (ULPA) filters to trap airborne particles. These filters are able to trap tiny particles with over 99% efficiency.

- Cleanroom Garments: Making sure cleanroom personnel wear appropriate garments, including bunny suits, head covers, beard covers, foot coverings, face shields, and gloves.

- Controlled Access: Limiting access to cleanrooms to trained personnel only. This also includes using tools such as pass-through chambers and air locks to limit contamination between spaces.

Similarly, when designing a cleanroom, it is important to select appropriate materials and airflow systems to meet standards. For example, cleanrooms often have non-porous surfaces to prevent the accumulation of particles in hidden or hard-to-reach places. This makes them much easier to clean and maintain.

Another important factor in keeping cleanrooms clean is airflow, and it is often designed to flow in a specific direction. In the industry, this is called unidirectional airflow (also known as laminar airflow), and it is just what it sounds like: air that flows in one direction. This could mean that it flows horizontally or vertically, depending on what the cleanroom will be used for. It helps remove particles quickly and is generally used in ISO 5 cleanrooms and stricter classifications.

For a tailored cleanroom solution that meets your specific requirements, get a free quote from Allied Cleanrooms today. As cleanroom experts, we can help you design and maintain a cleanroom that meets all ISO standards.

Industry Applications

Cleanrooms are important for manufacturing processes across various industries and are equally important in research. Here are a few examples of how different sectors use cleanrooms to meet their needs.

Pharmaceuticals

Cleanrooms in this industry have to meet strict regulations, such as GMP and cGMP, to prevent contamination of products during the manufacturing stages of compounding, filling, and packaging. ISO Class 5-7 cleanrooms are commonly used for sterile product manufacturing.

Semiconductor Manufacturing and Microelectronics

These industries require extremely clean environments. Sometimes, a single particle can cause major issues with products. Most semiconductor cleanrooms need to comply with ISO Class 4-6.

Aerospace and Defense

Precision and reliability are paramount in aerospace and defense manufacturing. This is because contamination of components can lead to catastrophic failures and even death. Cleanrooms in these sectors may be anywhere from ISO Class 3 to ISO Class 7.

Food and Beverage

While less strict than semiconductor and pharmaceutical cleanrooms, food and beverage environments still need to keep clean. ISO Class 7-8 cleanrooms are typical.

The Bottom Line

Cleanroom ISO standards, particularly ISO 14644-1, are important to the production of safe products and to reliable science. These standards provide uniformity to maximize cleanliness and comply with regulations. By understanding and applying ISO standards, companies can rest assured that their cleanrooms will operate effectively.