25 Apr 5 Trends and Innovations in Aerospace Cleanroom Technology

In the aerospace industry, safe and reliable products are impossible without cleanrooms. And since components will become smaller as technology advances, cleanrooms will need to become even better at removing contaminants. In this article, we’ll go over some of the key trends and innovations in aerospace cleanroom technology.

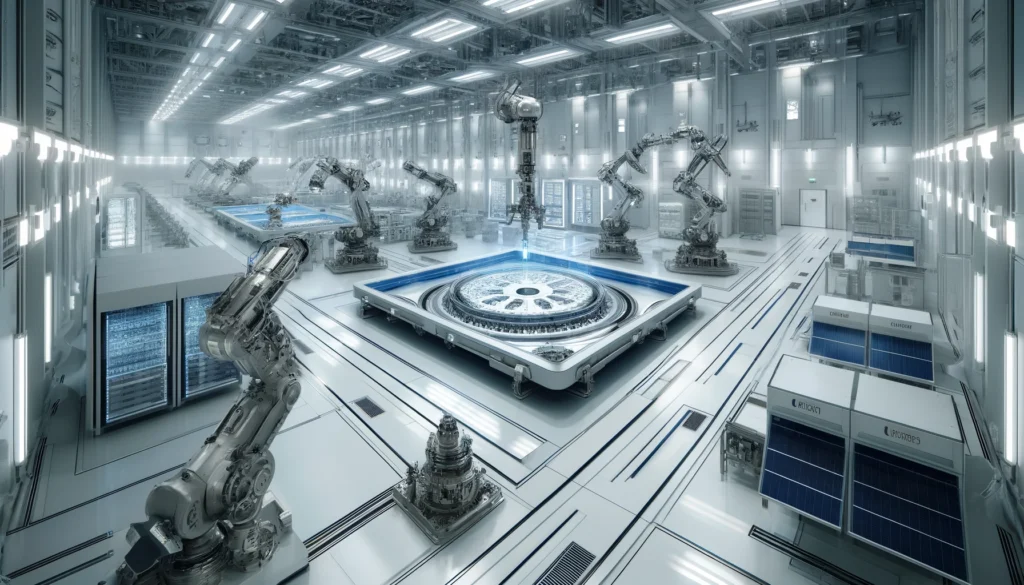

1. Automation and Robotics

The rise of automation and robotics is already affecting the cleanroom industry. Such systems improve manufacturing precision and, more importantly, reduce human presence.

Humans are often the main source of contamination in cleanrooms (according to some estimates, we make up 80% of cleanroom contamination), so the ability to manufacture products without as many people is a major step forward.

2. Advanced Filtration Technologies

Advanced filtration technologies are important to any cleanroom operation. As aerospace components become smaller, stricter particle control demands are inevitable.

Ultra-low particulate air (ULPA) filters, which remove 99.999% of particles that are 0.12 micrometers, have been indispensable since they were invented in the 1970s.

In the future, when aerospace parts become even smaller, new air filtration technologies will need to be invented in order to prevent tinier particles from disrupting products.

3. Real-time Monitoring Systems

Smart sensors are another technical advancement that will have an ongoing impact on the cleanroom sector. These sensors track a variety of cleanroom parameters in real time, including temperature, light, humidity, and particle levels. Having these IoT technologies in place allows firms to promptly identify and address issues.

4. Modular Cleanroom Designs

Modular cleanrooms are becoming the standard in modern aerospace facilities. They are flexible, and can be adapted to ongoing business changes. Additionally, they can be installed with minimal disruption to daily operations. (If you’re considering upgrading or implementing a new modular cleanroom, Allied Cleanrooms can help. Get a free quote to see how our solutions can meet your aerospace needs.)

5. Eco-friendly Materials and Practices

Environmental conservation is another rising priority. Eco-friendly materials that lessen their influence on the environment are being used more often in aerospace cleanrooms, particularly in modular cleanrooms. Similarly, energy-efficient systems can cut expenses overall and minimize waste.

Advancing Aerospace with Cleanroom Technology

Thanks to developments in cleanroom technology, the aerospace sector is poised for progress. These advancements promise to improve cleanliness and precision in aerospace manufacturing, while also boosting sustainability and ensuring industry compliance.