If you’re working with products that can’t handle dust or dirt, you already know you need super clean air. And that’s exactly what class 100 cleanrooms are for. It keeps tiny particles out, so your work stays safe. In this article, we’ll break down what a class 100 cleanroom is, some industries that use them, their design and requirements, and more.

What Is a Class 100 Cleanroom?

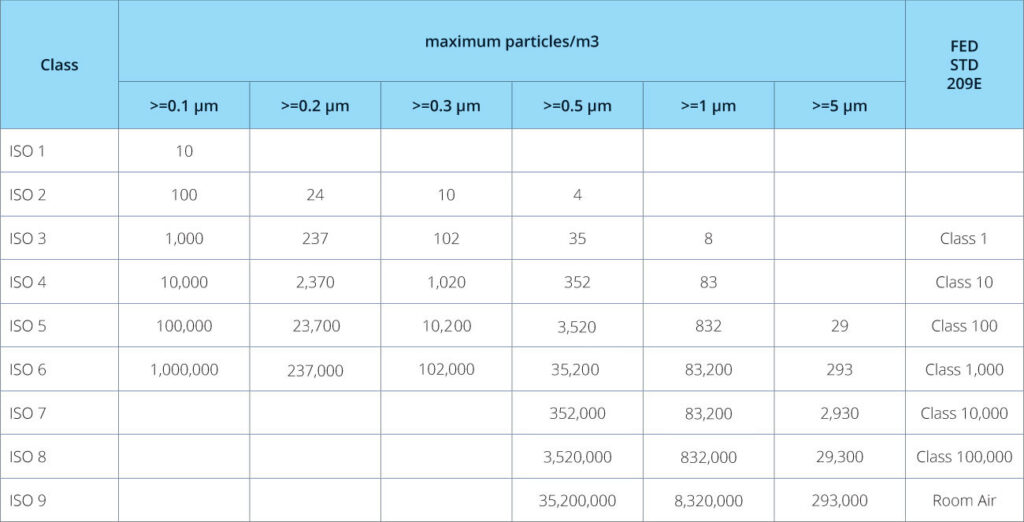

A class 100 cleanroom is a controlled environment where the air can’t have more than 100 particles (each at least 0.5 microns across) per cubic foot. The “class 100” name comes from an old U.S. standard called FED-STD-209E, but people still use it even though it’s now defunct.

The current standard is ISO 14644-1, and uses metric units, so particles are measured per cubic meter instead of per cubic foot. In this system, Class 100 matches up with ISO Class 5. They are the same level of cleanliness, just with different numbers.

When compared to class 10000 and more lenient spaces, class 100 cleanrooms don’t just limit the bigger particles, they also keep the smaller ones (like 0.1 or 0.3 micrometers) in check. See the chart above for the specific sizes measured in each class.

What Industries Use Class 100 Cleanrooms?

Class 100 cleanrooms are used in industries where microscopic contamination can damage products, materials, or research. Uses include:

- Electronics manufacturing

- Pharmaceuticals (filling rooms)

- Food & beverage manufacturing

- Biotech

- Film manufacturing

- Aerospace

- Solar

- Nanotechnology

- Semiconductors (wafer chips, photolithography)

- Medical devices

Class 100 Cleanroom Design and Requirements

In order to design a class 100 cleanroom, you’ll need to meet strict requirements, whether for ISO or more industry-specific guidelines. Here are a few important features that matter most when you’re putting one together.

1. Materials and Layout

In general, materials, surfaces, and layouts in a class 100 cleanroom need to stop particles from sticking, be simple to clean, last a long time, and should be designed such that the most vulnerable areas are protected. As a result, you’ll usually find the following:

- Non-shedding wall and ceiling panels (powder-coated steel, FRP, stainless steel)

- Seamless flooring (epoxy or vinyl)

- Gowning rooms

- Airlocks and pass-through chambers

- Zoned layouts to separate vulnerable and non-critical areas

2. Airflow and Pressure

To stay within particle limits class 100 cleanrooms usually require the following:

- Unidirectional (laminar) airflow across the entire space

- Ceiling-mounted fan filter units (FFUs)

- Air velocity between 0.3 and 0.5 meters per second

- Positive pressure

- Floor- or wall-mounted air returns

- 240 to 600 air changes per hour (ACPH)

- Ceiling coverage between 35% and 70%

3. Filtration

Furthermore, class 100 cleanrooms at this level use either:

- HEPA filters (99.97% efficiency at 0.3 microns)

- ULPA filters for extra-sensitive applications (99.999% efficiency at 0.12 microns)

4. Environmental Conditions & Monitoring

Finally, like most other strict cleanrooms, class 100 spaces must be monitored. Some standard parameters include:

- Temperature control (typically 68 to 72°F)

- Relative humidity between 30 to 50%

- Real-time particle counters and pressure gauges

- Digital control panels with alert systems

The Bottom Line

Class 100 cleanrooms (ISO 5) only let in 100 tiny particles (0.5 micrometers or more) per cubic foot of air. They use laminar airflow, special filtration, and environmental monitoring systems to meet the standards. You’ll find them in places like computer chip factories, biotech labs, pharmaceutical manufacturing, or anywhere that strict controls are necessary.