In some industries, creating high-quality products or research depends in large part on the environment they are conducted in. Organizations may use a variety of controlled environments, such as dry rooms and cleanrooms, to protect these products and processes. In this article, we’ll cover what a dry room is, how they compare with cleanrooms, and also provide some common applications and design elements for them.

What is a Dry Room?

A dry room is a controlled environment wherein humidity levels are kept very low to protect sensitive materials, equipment, and products from moisture-related damage. These rooms are essential in industries where humidity can cause significant damage, such as pharmaceuticals, electronics, aerospace, and food production. Their main purpose is to create a low humidity environment, but they may achieve this through controlling other variables as well, such as temperature and air circulation.

What Does a Dry Room Do?

As we mentioned previously, the primary function of a dry room is to keep humidity levels low. This is achieved through advanced dehumidification systems and HVAC (Heating, Ventilation, and Air Conditioning) controls.

In a typical room, humidity levels can range from 30% to 50%.

By contrast, a dry room often maintains humidity levels below 10%, and in some cases, as low as 1%, depending on the specific requirements of the industry.

For example, dry rooms used in lithium battery production can get to less than 1% relative humidity.

By keeping humidity levels consistently low, dry rooms prevent moisture from damaging products or research.

Cleanrooms vs. Dry Rooms: What’s the Difference?

| Cleanroom | Dry Room | |

|---|---|---|

| Purpose | Controls the size and number of particles in the air. | Focuses on controlling humidity. |

| Design | Uses HEPA filters and airflow systems to remove particles. | Uses dehumidifiers and specialized HVAC systems to keep humidity levels low. |

| Applications | Common in pharmaceuticals, biotechnology, and semiconductor manufacturing. | Used in pharmaceuticals, electronics, aerospace, and food production. |

| Environmental Controls | Strict control over particles, temperature, and sometimes humidity. | Primarily controls humidity with less emphasis on particle control. |

Cleanrooms control the size and number of particles in the air, such as dust and microbes, to create a contamination-free environment.

Dry rooms, on the other hand, focus specifically on controlling humidity to protect moisture-sensitive materials and processes.

Design

Both clean rooms and dry rooms have specialized designs and equipment, but their focus differs.

Cleanrooms use HEPA filters and airflow systems to remove particles, while dry rooms use dehumidifiers and specialized HVAC systems to create and sustain low humidity levels. The materials used in construction may also differ to support these distinct functions.

Applications

Cleanrooms are common in industries such as pharmaceuticals, biotechnology, and semiconductor manufacturing, where particle contamination can disrupt product quality.

Dry rooms are essential in sectors like pharmaceuticals, electronics, aerospace, and food production, where moisture control is critical.

Environmental Controls

Cleanrooms strictly control particles, temperature, and sometimes humidity, depending on the application.

Dry rooms, on the other hand, primarily control humidity, with less emphasis on particle control.

With respect to environmental controls, we could say that cleanrooms are more inclusive than dry rooms.

Applications of Dry Rooms

In the pharmaceutical industry, dry rooms are important for storing and processing hygroscopic materials—substances that absorb moisture from the air. These materials can degrade or lose effectiveness if exposed to high humidity. Dry rooms help ensure the stability and quality of medications.

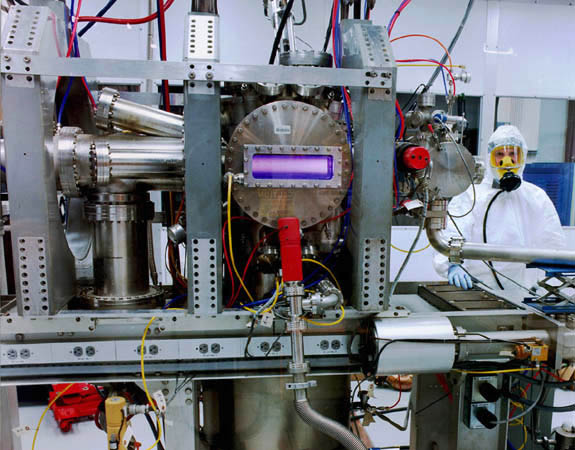

Electronics Manufacturing

Electronics manufacturing is another area where dry rooms are useful. Moisture is known to damage sensitive parts, and this, of course, can lead to product failures. Dry rooms provide the necessary environment to assemble and store electronic devices.

Aerospace

The aerospace industry uses dry rooms for the production and assembly of components that must remain free from moisture. High humidity can lead to corrosion and other issues, compromising the safety and performance of aerospace parts. Dry rooms help preserve the integrity of components.

Food Industry

In the food industry, dry rooms are used to store and process products that are sensitive to moisture. For example, dry rooms help prevent spoilage and contamination in powdered foods, spices, and dried fruits. Dry rooms help extend the shelf life and quality of such products.

Design Elements of Dry Rooms

Surfaces and Materials

Dry rooms use specialized walls, floors, and ceilings designed to minimize moisture infiltration. These elements often use materials that resist moisture absorption, such as stainless steel or epoxy-coated surfaces. Insulated panels and sealed joints are important to prevent humidity from entering the room.

HVAC Systems and Dehumidifiers

One of the most important components of a dry room is its HVAC system, which works alongside dehumidifiers to reach low humidity levels. The HVAC system controls temperature and air quality, while dehumidifiers remove excess moisture from the air. Together, these systems create a stable, dry environment.

Benefits of Using Dry Rooms

Product Quality

Dry rooms ensure that products are free from moisture-related defects, which improves their quality and reliability.

This is particularly important in industries like pharmaceuticals and electronics, where even a small amount of moisture can cause serious issues.

Safety

By controlling humidity levels, dry rooms reduce the risk of contamination and corrosion. This makes processes safer and more efficient, especially in sensitive industries like aerospace and pharmaceuticals.

Increased Productivity

Preserving low humidity levels helps optimize production processes. Equipment runs more smoothly, and there are fewer delays or issues caused by moisture. This leads to higher productivity and efficiency in manufacturing and storage operations.

Cost Savings

Although the initial setup of a dry room can be expensive, the long-term benefits often outweigh the expenses. Improved product quality, reduced waste, and increased efficiency lead to significant cost savings over time.

The Bottom Line

Dry rooms play an important role in many industries by providing a controlled environment where humidity levels are kept exceptionally low. This control is important for product quality, safety, and efficiency. Whether in pharmaceuticals, electronics, aerospace, or food production, dry rooms help ensure the integrity and success of many processes and products.