Medical Devices & Diagnostics Cleanrooms

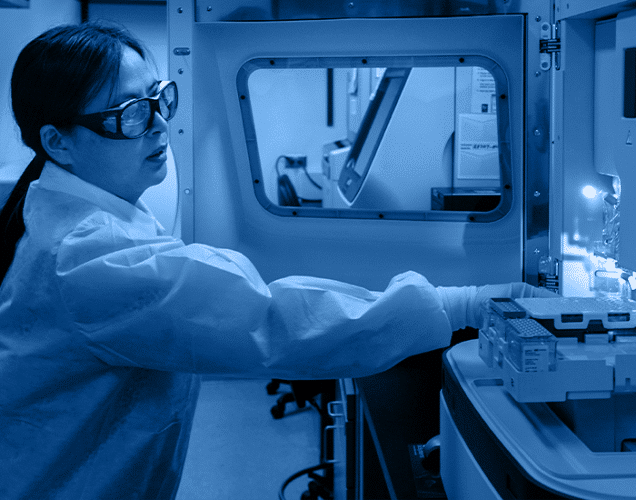

Medical device cleanrooms are not optional upgrades. They are the frontline defense against microbes and particles that could turn life-saving implants into liabilities. For devices piercing the skin like catheters or pacemakers, even trace contaminants spell patient harm and shutdowns. Diagnostics cleanrooms ensure PCR tests or blood analyzers deliver accurate results without false positives from airborne invaders. Skip this control, and your quality system crumbles under 21 CFR Part 820 scrutiny, inviting fines that devour profits.

These environments tackle viable bacteria and non-viable dust through engineered barriers, aligning with GMP’s core demands for repeatable quality. Facilities prioritizing this see rejection rates plummet by 30%, freeing capital for R&D in wearables or point-of-care diagnostics. Do not chase after-the-fact fixes. Build medical device manufacturing cleanrooms that preempt risks from day one. Get it right, and your operation hums with the reliability regulators crave.

Design Features That Power Flawless Med-Tech Performance

Kick off with walls that defy chemical assaults. Smooth FRP or aluminum panels seal tight, shrugging off disinfectants without shedding fibers. Heat-welded vinyl floors with integral coves trap zero grime, making swab tests a formality and microbial hotspots extinct. Ceilings rigged with cleanroom grids channel laminar flow, starving particles of escape routes in high-stakes assembly zones. The outcome is simple: cleaning downtime halves, labor costs drop, and your sterile line runs uninterrupted.

HEPA/ULPA filters in positive-pressure setups cascade clean air from core to corridors, fortifying against cross-contamination in diagnostics cleanrooms. Gowning airlocks and pass-through cabinets segment flows, ensuring techs do not drag in chaos from the outside.

Digital sensors lock in temperature, humidity, and differentials, preventing drifts that breed failures in orthopedic implants. Automated monitoring flags anomalies in real time, converting threats into 24/7 safeguards. Med-tech pros report 25% fewer non-conformances when these elements click.

Real-World Applications: From Implants to Diagnostic Breakthroughs

Medical device cleanrooms fuel everything from stent crimping to syringe filling. Implants demand ISO 5 rigor where a speck could trigger rejection. Orthopedic producers thrive here, assembling joints particle-free to dodge post-op infections that cost hospitals millions. Diagnostics cleanrooms shine in PCR labs or kit packaging, where humidity tweaks ensure reagent stability and test accuracy soars. External wearables like glucose monitors assemble seamlessly, hitting market shelves without sterility hiccups.

Packaging suites under ISO 5 laminar hoods seal the deal, shielding final products through sterilization without recontamination. Supplier operations for injection molding or sub-assemblies scale affordably in ISO 8 setups, feeding your main line with vetted components. Whether chasing oncology tools or IV kits, smart zoning cuts human error by design. Producers nailing applications like these slash lead times, grabbing 20% more shelf space in a crowded med-tech arena. It is not scale for scale’s sake. It is targeted builds that propel your niche to profitability.

Cracking Cleanroom Classifications: Align ISO Levels to Device Risks

ISO 5 (Class 100) cleanrooms rule for implantables like pacemakers, snaring 99.999% of 0.3-micron particles to safeguard invasive operations. Dial to ISO 6 (Class 1,000) for semi-critical diagnostics gear, balancing sterility with cost for blood analyzers. ISO 7 (Class 10,000) buffers assembly of Class II syringes, while ISO 8 (Class 100,000) handles gowning or non-sterile wearables packaging. Mismatch, and you are courting 483 observations. Align it, and validation sails through. EU parallels via ISO 14644 amp up monitoring for global plays.

These classes are not checkboxes. They sync particle caps to your device’s invasion depth, from mucosal contacts to full implants. Med-tech vets who spec early dodge retrofits that eat six figures. Layer in airflow velocity checks per ISO 14644-2 for proof of performance. The payoff is a facility that flexes from R&D to volume without compliance stumbles. Precision classification is not theory. It is your ticket to unassailable audits.

Modular Med-Tech Cleanrooms: Your Scalable Path to Dominance

Modular medical device cleanrooms wire in FDA GMP and ISO 13485 from the blueprint, evading the six-month slogs of stick-built nightmares. Coved corners and seamless epoxy floors endure wipe-down marathons, trimming upkeep by 35% over legacy setups.

IQ/OQ/PQ packets hand regulators pre-chewed validation, fast-tracking 510(k) nods. Start lean for prototyping, bolt on suites for surges in diagnostic demand, and expand post-approval without halting lines. Results scream ROI in under a year with disruptions at zero.

Non-shedding steel panels and ESD-safe vinyl adapt to electrostatic whims of sensor assembly, simplifying microbial sweeps. Firms flipping to modular log 50% quicker deploys, outpacing rivals to FDA clearance. Prioritize outcomes with facilities that endure, evolve, and eclipse the competition. Modular mastery turns capital expense into compounding gains.

Compliance Mastery: FDA GMP, ISO 13485, and the Full Arsenal

FDA’s 21 CFR Part 820 mandates premises that cradle quality from molding to pouching, with GMP enforcing HEPA integrity and gowning drills. ISO 13485 overlays risk-based QMS, demanding traceable controls for every catheter curve. ISO 14644 classifications set the particle bar, while USP 797 nods to compounding-adjacent devices. Breach this, and Form 483s cascade into shutdowns eroding market trust. Fortify upfront, and your med-tech cleanroom weathers inspections like a fortress.

Viable sampling and particle logging via automated dashboards halve prep drudgery, proving sustained control. Leaders weaving in Annex 1 for EU harmony export without rework. The mission is simple: standards as turbochargers, not brakes on innovation. Compliance locked means you can scale your implants or diagnostics line with ironclad assurance.

Customization: Engineer Your Cleanroom for Med-Tech

Choose hardwall fortresses for implant precision or softwall flexibility for diagnostic prototyping, matching your throughput blueprint. ESD epoxy floors zap static in wearable builds, while antimicrobial vinyl guards PCR benches from biofilms. Integrate particle counters with AI alerts, logging data for seamless 13485 audits. Weave in DI water feeds or nitrogen purges for sterile fills, plus laminar benches for final seals. Tailored this way, your space morphs cost centers into cash cows.

Built for Sterility

Implants, diagnostics, and wearables need particle-free assembly. Medical device cleanrooms at ISO 5–8 levels use HEPA/ULPA air, seamless walls, and strict gowning to keep contaminants out.

Faster to Approval

Modular setups deploy faster and validate quicker. With IQ/OQ/PQ in place, 510(k) sign-offs move sooner and lines keep running.

Compliance Ready

FDA 21 CFR Part 820, ISO 13485, and ISO 14644 are the standards these need to meet. Get those in place early and audits, exports, and growth stay on track.

Contact

Leave Your Cleanroom in Expert Hands

FAQs About Cleanrooms for Medical Devices & Diagnostics

What ISO cleanroom classes are required for implants compared to external devices?

ISO 5-6 for implants like stents. ISO 7-8 suffices for externals like syringes.

How do medical device cleanrooms hit FDA GMP?

They hit FDA GMP through validated HVAC, gowning protocols, and continuous monitoring per 21 CFR 820.

What are the best wall and floor materials?

The best wall and floor materials are smooth FRP for walls and heat-welded vinyl floors for chemical resistance and zero shedding.

Are modular diagnostics cleanrooms ISO/FDA viable?

Absolutely. Scalable panels meet classifications with faster validation.

How do you validate a cleanroom for FDA sign-off?

Run IQ/OQ/PQ with particle and microbial tests, documented per GMP.