Project Overview

For over ten years, Wondfo USA has been providing top-quality toxicology, pregnancy and fertility, and veterinary testing kits to the medical and veterinary markets across the USA. Their product portfolio includes the manufacture and distribution of a wide range of products for the rapid identification of cardiovascular diseases, inflammation, tumors, infectious diseases, drug abuse, and pregnancy.

The company has seen continued growth that has led them to expand production throughout the United States. In 2020, Wondfo USA was looking to expand the production of their medical testing kits to the West Coast. They required a 14,000 square foot climate-controlled environment to be built inside a warehouse facility in San Diego, California.

Upon researching several West Coast cleanroom companies, Wondfo’s Head of Facilities reached out to Allied Cleanrooms to help design a solution that exceeded the strict requirements for the manufacture of medical testing kits.

Solution

The Wondfo USA project was unique in many ways. Although the project did not require an ISO classification, it did require that the environment be both temperature and humidity controlled across over 14,000 square feet and 20 individual rooms.

Allied Cleanrooms worked with the team at Wondfo USA to design a solution that utilized 25 tons of air conditioning to maintain a consistent ambient air temperature of 68 degrees Fahrenheit. A large desiccant dehumidifier was installed to maintain a relative humidity of 25% throughout the entire manufacturing facility.

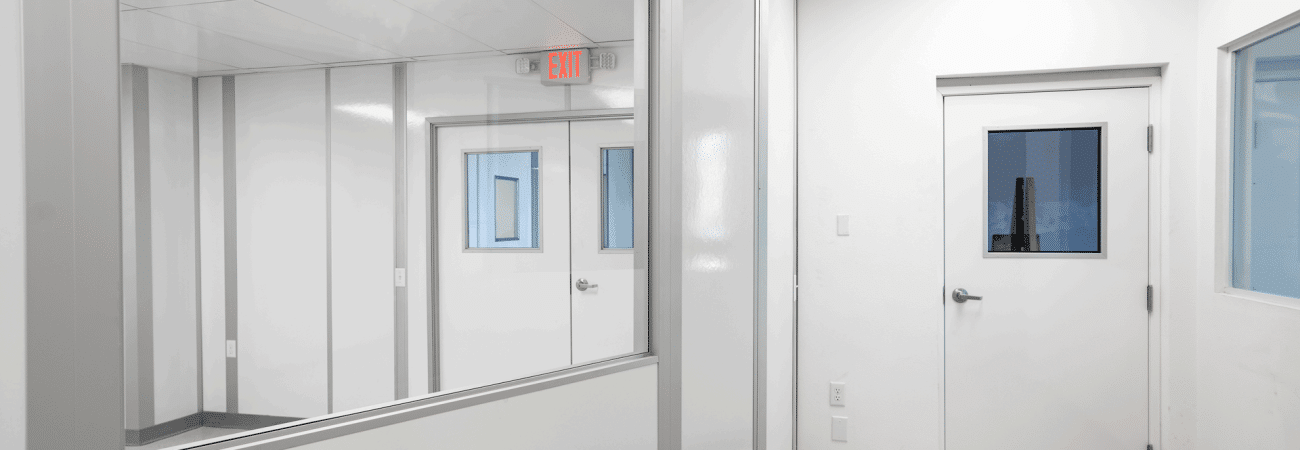

The rooms were designed to ensure a clean manufacturing process, with fiberglass-reinforced panel walls, powder-coated doors, and cleanroom pass-throughs where needed.

Additionally, Allied Cleanrooms designed and installed two second-story mezzanine offices and a first floor employee breakroom

Project Challenges

Allied Cleanrooms operated as the general contractor on the project. The entire scope of work — from the modular wall system, HVAC, electrical, plumbing, and even the tile in the reception area — was managed by Allied Cleanrooms. This presented an interesting challenge as some of these trades are outside the normal scope of a cleanroom installation.

Allied Cleanrooms needed to source qualified subcontractors to perform the work that was ancillary to the cleanroom installation.

Additionally, operating as the general contractor meant that Allied Cleanrooms was responsible for pulling the required permits on all trades involved in the build-out as well as overseeing all subsequent inspections.

Despite the broad scope of work, Allied Cleanrooms was able to deliver another successful project that was on time and within the prescribed budget.

Leave Your Cleanroom in Expert Hands

- 35+ years of experience

- Compliance for ISO, FDA, cGMP, USP, and many other standards

- Coast-to-coast service

- All design, engineering, and production done in-house