ISO Classifications

What are ISO Cleanroom Classifications?

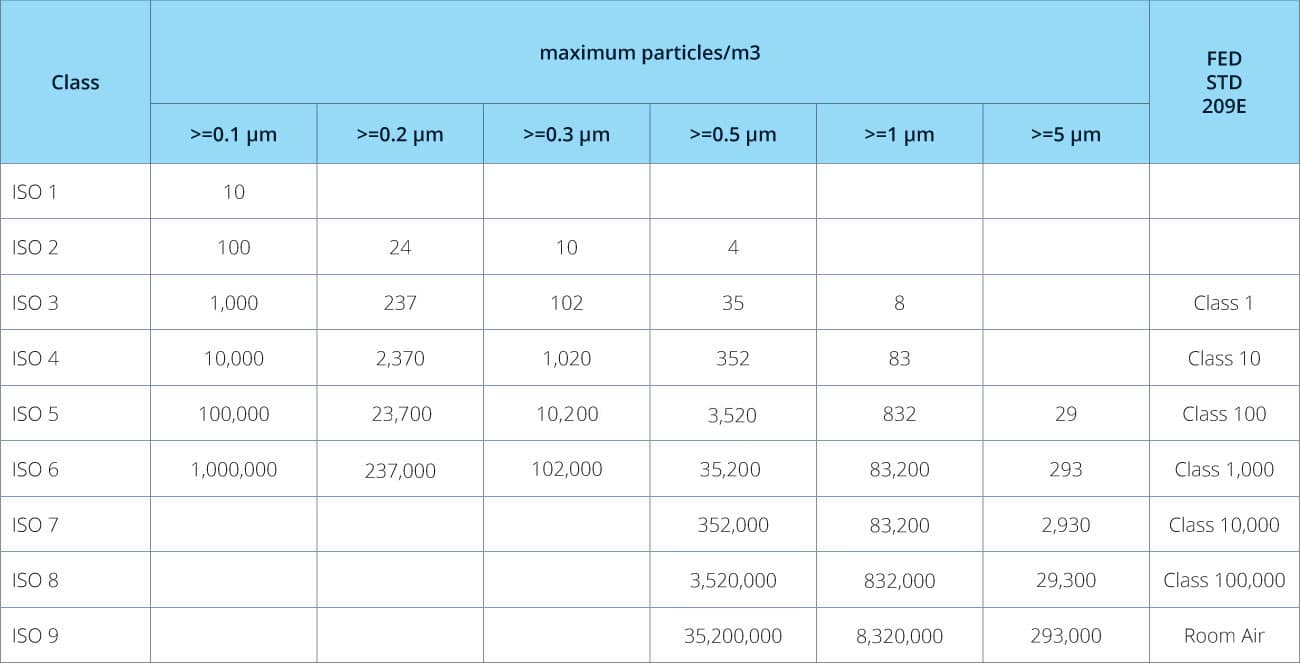

ISO cleanroom classifications are categories that outline how clean a controlled environment is. They run from ISO 1 to ISO 9, and are determined by the number and size of particles present per cubic meter of air. They are set by the ISO 14644 standard, and the section called ISO 14644-1 specifically defines the categories.

A Few Examples

To show how ISO classifications differ, let’s start by taking the air quality in a typical urban city. Let’s say it has 35,000,000 particles per cubic meter, each of which is 0.5 μm (μm = micrometer) or larger. This area would be classified as ISO 9, which is not necessarily a cleanroom, but is the category associated with normal air.

At the other end of the spectrum, there are ISO 1 cleanrooms, which allow no more than 10 particles per cubic meter that are 0.1 μm or larger, and only 2 particles that are 0.2 μm or larger. This type of space, as you may well imagine, is difficult to create (and especially to sustain). A scratching of the head or sneeze could significantly affect the work being done, and for this reason they are quite rare.

Finally, let’s consider an ISO 5 cleanroom, which seems to be in the “middle” between 1 and 9 (though technically, this is still a very strict space). These spaces only permit 100,000 particles per cubic meter at 0.1 µm, while an ISO 4 cleanroom, which is even stricter, permits up to 10,000 particles per cubic meter of the same size.

Notice that the number of particles differs by one order of magnitude, so even though ISO 4 and ISO 5 are only one number apart, a lot more effort will have to go into building the former than the latter. All this goes to show that there can be big differences in requirements, features, and costs between classes that differ by only one or two levels.

How Particle Counts Work

Take a look at the ISO 14644-1 cleanroom standards table. You may notice that some ISO classes do not include certain particle sizes. For example, ISO 8 cleanrooms don’t measure sizes 0.1 µm and larger, ISO 3 cleanrooms don’t measure sizes 5 µm and larger, and so on.

This is for two main reasons. First of all, the number of particles in a particular size range may be too high to measure. In other words, there may be so many particles of a particular size that trying to measure them would be difficult if not meaningless.

Secondly, for each cleanroom class, there are only a handful of particle sizes that are focused on, and the reason for this is that those are the sizes that cause the most problems to the work being done within the space. In pharmaceutical cleanrooms, for example, particles that are 0.5 μm or bigger may bring microorganisms with them, which of course may contaminate medicines. As a result, these need to be prevented from entering the most.

Furthermore, you may also notice that the maximum particle counts in cleanroom classification are cumulative, since they include particles that are bigger than the defined size. All this means is that sometimes particles will be counted in multiple categories.

Here are a couple examples of how this works:

- If a particle is 2 μm, it needs to be included in the count for particles 2 μm or greater. But, it is also counted again in the categories that are smaller than 2 μm (where relevant).

- In the same way, a particle that is 5 μm is counted both in the group for particles 5 μm and larger, and also counted in the successively smaller categories.

In short, a single particle is often counted multiple times.

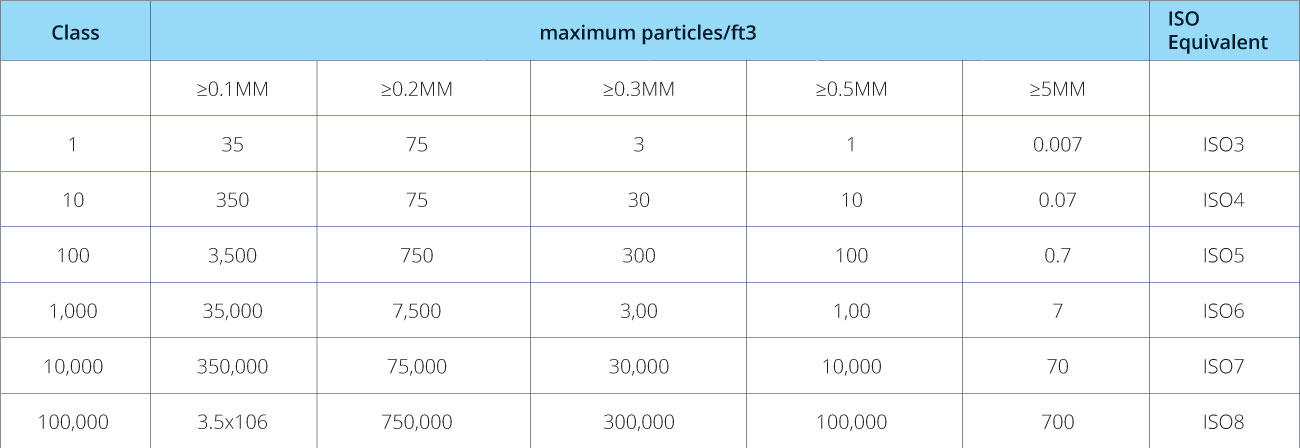

What Is Federal Standard 209E ?

Historically, the Federal Standard 209E was the go-to classification system. It categorized cleanrooms based on the size and number of particles per cubic foot of air, rather than per cubic meter, as is the case with ISO classifications.

In 2001, however, the Federal Standard 209E was replaced by the ISO 146441 standard. The language has not been fully carried over yet, though, and terms like “Class 10,000” or “Class 1,000” are still used today.

Also, if you take a look at the table above, you may notice that the ISO classes are equivalent with classes in FED-STD-209E, and this explains why these terms are so often used interchangeably.

FAQs About ISO Cleanroom Classifications

How are cleanroom classifications verified?

Testing and certification are done using particle counters, airflow measurements, and other environmental monitoring. Such tests are performed both “at-rest,” which means without staff present but including equipment, and “in operation,” which includes staff and equipment.

Can one cleanroom meet multiple ISO classifications?

Technically, yes. In fact, a cleanroom with multiple rooms or zones that have different classifications is quite common (especially in the pharmaceutical industry). In many of these spaces, you progressively work your way from an ISO 7/ISO 8 space to stricter ones, such as an ISO 5, where the most important work happens. The other rooms may serve as buffer rooms, gowning rooms, or anterooms.

Does ISO 14644 cover bacteria/microbes and other living particles?

No, it only focuses on non-viable (non-living) particle counts. The control of microorganisms is covered in other industry standards, such as GMP and USP 797.

Leave Your Cleanroom in Expert Hands

- 35+ years of experience

- Compliance for ISO, FDA, cGMP, USP, and many other standards

- Coast-to-coast service

- All design, engineering, and production done in-house