Aerospace Cleanrooms

A cleanroom for aerospace companies is a facility where satellites, spacecraft, aircraft engines, and military optics are all produced. The smallest particles of matter, minute changes in humidity, or outgassing of materials can affect performance. Failures in the industry can lead to the death of personnel and millions of dollars wasted.

The aerospace cleanrooms that NASA builds for spacecraft manufacturing are highly controlled environments. The lives of astronauts and the protection of valuable equipment make them more critical than in other sectors.

Particle contamination can ruin payloads; electrostatic discharge will destroy sensitive aircraft avionics. Outgassing can cloud optics or ruin satellites. Even minute fluctuations in pressure and humidity can affect test results or weaken materials used.

As a result, aerospace cleanrooms construct their own special environments where the mechanical, thermal, chemical, and electrical properties of critical components are controlled tightly in place. They are the unseen infrastructure that allows spacecraft to fly, aircraft to operate free from defects, and military equipment to remain unconditionally reliable.

Why Aerospace Cleanrooms Are Different

An aerospace cleanroom is not the same as a pharmaceutical or semiconductor cleanroom. In aerospace, the risks are magnified, and there is no room for error.

Compared to pharmaceutical or semiconductor cleanrooms, aerospace cleanrooms involve larger construction projects that progress in stages and require strict compliance.

- Oversize assembly: Spacecraft payloads and aircraft engines require facilities with large spans. Modular cleanroom construction in general allows clear spans of 20 feet without columns, and larger spans are also feasible if the project requires it.

- Product adaptability: Modular systems allow reconfiguration for prototype testing today and mission integration tomorrow.

The major difference from a pharmaceutical cleanroom, which is designed to isolate products from people, is that aerospace cleanrooms aim to protect both humans and valuable equipment.

Design And Features That Deliver Results

When billions of dollars or the existence of a mission are at stake, details make all the difference. Features in cleanrooms for aerospace incorporate safeguards against every conceivable danger:

- Walls and ceilings: Modular, insulated, contamination-resistant, and in sizes big enough to accommodate aerospace hardware that is anything but small.

- Clean spans: The standard idea in modern construction is a 20-foot span with no columns, but the engineers have ways to make it happen beyond 20 feet.

- ESD-safe flooring: Vinyl finishes can prevent damage to systems from electrostatic discharges, and epoxy floors are extremely durable and easy to clean.

- Air handling systems: HEPA/ULPA filtration, laminar flow, and customizable air change rates keep particle control strict.

- Environmental monitoring: Even when using modular, there are systems that track in real-time particle counts, pressure, temperature, and relative humidity.

- No outgassing: Silicon-free materials do away with possible contamination of optics and sensors.

- Additions: Air showers, gowning rooms, pass-throughs, HVAC integration, and fire suppression systems.

Some of these are not optional features. They are mission-critical defenses against expensive failures before they happen.

Cleanroom Classifications in Aerospace and Defense

Cleanroom classifications differ according to the type of aerospace project involved.

- ISO 7-8 (Class 10,000–100,000): Defense assemblies, aircraft engines, and mechanical components.

- ISO 6-7: Space module integration and payload assembly.

- ISO 5-6: Satellite optics, lasers, and sensors. These systems are so sensitive that even one particle can throw them off totally.

The leading facilities are designed for changing classifications as projects evolve from prototype assembly to final test phase.

Compliance Is More Than Just an Option

In aerospace and defense, compliance is non-negotiable, and modular cleanrooms go beyond the toughest standards:

- Safety classifications according to ISO 14644-1/2 (from ISO 5 up to ISO 8).

- ASTM E2352: Standards for modular and portable cleanrooms in aerospace applications.

- Integration: an array of systems in one seamless envelope integrate HVAC, filtration, flooring, and environmental monitoring.

- NASA contamination control requirements for spacecraft and payload assembly.

- Defense regulations that encompass ITAR and MIL-SPEC.

Every connection, surface, and airflow system can be tailored for greater reliability, ensuring the cleanroom is mission ready.

Applications Across Aerospace & Defense

Areas of application for aerospace cleanrooms are many, varied, and high-stakes:

- Spacecraft and Satellites: Everything from R&D and materials selection to payload assembly and prelaunch testing.

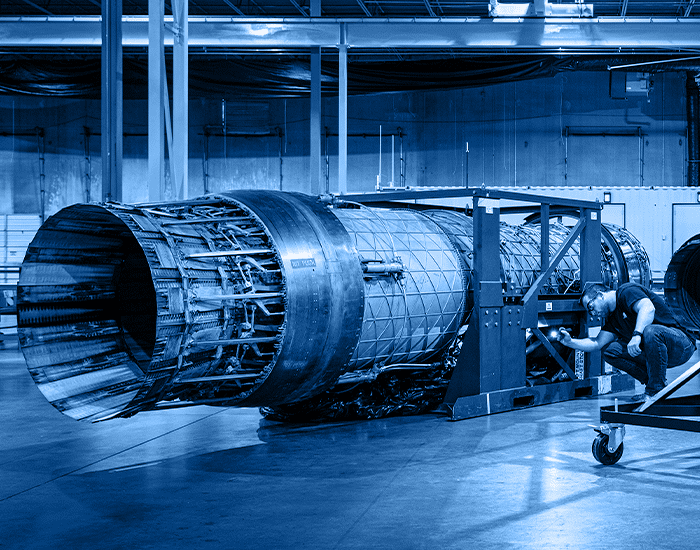

- Aircraft Engines: Building and inspecting engines for aircraft, as well as all stages of manufacturing, assembly, and service.

- Communication Assemblies: Secure communication systems, laser technologies, and avionics for defense applications.

- Sensors and Optics: Infrared sensors, telescopes, and precision lenses that require absolute cleanliness.

- Laboratories: Prototyping labs may be modular sites for aerospace defense projects in progress.

- Speed: Modular systems can be deployed in weeks or months, not years. Compliance ensures that ISO, ASTM, NASA, and defense standards are met from the start. The best part? Your technicians can concentrate on constructing hardware instead of waiting for the building to be ready.

Your Process – Your Aerospace Cleanroom

Moving into aerospace requires more than just buying an off-the-shelf enclosure. It calls for engineering to match the facility with your processes and workflows. The process involves:

- Consultation: Identifying the enclosure requirements, contamination risks, and compliance needs.

- Design & Engineering: A custom solution that is modular, and adaptable to match customer workflows.

- Integration: An array of systems in one seamless envelope to integrate HVAC systems, filtration, flooring, and environmental monitoring.

- Deployment: Installed and/or overseen by factory-trained professionals on your timeline.

- Adaptation: As missions change, facilities may expand, reconfigure, or upgrade.

It’s not just a cleanroom. It’s a tool for mission success. Whether you are making satellites, engines, or defense optics, success or failure depends on contamination reduction and compliance.

Protect Your Mission

Tiny particles, humidity changes, and outgassing from materials can jeopardize important missions. Aerospace cleanrooms give you strict control over manufacturing so that you can save billion-dollar projects as well as human lives.

Scalability

From engines to payloads, aerospace projects demand massive spans without columns. Modular cleanrooms deliver 20-foot clear spans and beyond, while adapting layouts for prototype work or final integration.

Compliance Assured

Aerospace cleanrooms go beyond standard pharma or semiconductor specs. They meet ISO 5–8 classifications, ASTM E2352, NASA contamination control requirements, and defense standards like ITAR and MIL-SPEC. Compliance is built into every surface, airflow, and system from the start.

Contact

Leave Your Cleanroom in Expert Hands

FAQs About Aerospace Cleanrooms

What ISO class of cleanroom is needed for building satellites?

Satellite assembly and optics work usually require ISO 5 or ISO 6 cleanrooms, since these processes demand stricter particle control during manufacturing and payload integration.

What is the difference between aerospace cleanrooms and pharmaceutical cleanrooms?

Pharmaceutical cleanrooms protect people from contamination. An aerospace cleanroom protects the hardware from being contaminated.

What is the role of ESD protection?

It stops a static discharge from ruining avionics, sensors, and electronic equipment.

What do non-outgassing materials do?

They prevent vapors from being released, which could fog optics or damage sensitive satellite components.

Can modular aerospace cleanrooms be moved or expanded?

Yes! Modular cleanrooms are designed to be reconfigured, expanded, or moved as your mission evolves.